The logistics industry is reeling under pressure because of shrinking profit margins and rising customer demands. Manual planning, paper tracking, and decisions based on guesswork no longer deliver satisfactory outcomes. In such a scenario, companies face an important choice: adopt AI-based operations or see their competitors move ahead.

The business case for AI transcends market hype. Companies using AI for logistics see significant efficiency gains and cost savings. Their supply chains reduce forecasting errors. Their production planning becomes better, too. And these are verified results from companies already running AI-based operations, not just projections. Companies that treat AI as optional may soon lose ground to those who see it as essential for survival.

A recent McKinsey report indicated that businesses that include AI in logistics experience a 15% decrease in expenses and a 35% growth in operational effectiveness. This highlights AI’s undeniable potential for businesses looking to stay ahead in a competitive market.

This blog explores in detail the role of artificial intelligence in the logistics sector, offering practical insights and real-life examples to trigger your business transformation.

Table of Contents

Importance of AI in the Logistics Industry

Primary Use Cases of AI in Logistics and Transportation

How to Overcome AI Adoption Challenges in Logistics

Steps to Implement AI in Logistics Operations

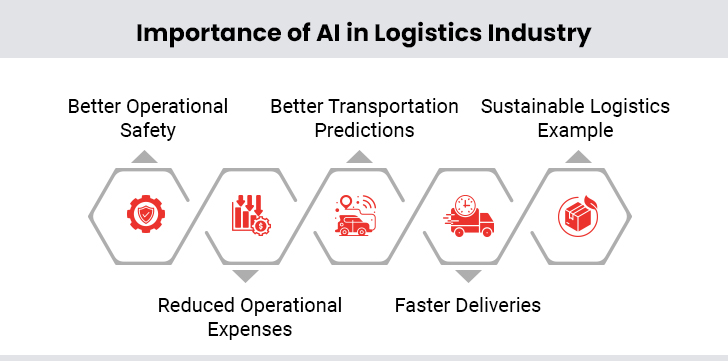

Importance of AI in the Logistics Industry

Modern logistics operations involve various stakeholders, changing customer demands, and dynamic obstacles such as traffic, weather, and geopolitical risks. Artificial Intelligence in logistics offers ground-breaking solutions that extend beyond just improving efficiency, playing a key role in driving innovation and sustainability.

I. Better Operational Safety

AI enhances safety by forecasting maintenance requirements for vehicles and equipment, reducing the occurrence of breakdowns and accidents. By maintaining the reliability of equipment, logistics companies can prevent disruptions and lessen operational risks.

II. Reduced Operational Expenses

AI reduces expenses by optimizing routes, automating manual tasks, and accurately forecasting inventory requirements. These efficiencies result in significant reductions in labor and fuel costs, increasing the cost-effectiveness of logistics operations.

III. Better Transportation Predictions

AI leverages real-time data to forecast potential delays caused by traffic, weather, or other factors. This enables businesses to proactively reroute shipments, minimizing disruptions and ensuring timely deliveries. AI uses real-time data to predict possible setbacks due to traffic, weather, or other elements. This allows businesses to proactively redirect shipments, reducing interruptions and ensuring deliveries happen on time.

IV. Faster Deliveries

AI decreases delivery times and improves customer satisfaction by making order picking in warehouses more efficient and optimizing last-mile delivery. This process is further expedited by incorporating self-driving vehicles and drones into delivery fleets. An example would be Amazon Prime Air testing drones to accomplish quicker, more environment-friendly deliveries.

V. Sustainable Logistics

AI has a critical impact on sustainability through the reduction of carbon footprints. It optimizes transport routes, reduces energy usage, and prevents wastage, aligning logistics with global sustainability objectives.

These benefits highlight why the logistics sector is putting more and more money into AI solutions. By tackling operational roadblocks and encouraging innovation, AI is changing logistics into a more intelligent and resilient sector.

Learn How AI Can Improve Operational Efficiency in the Retail Sector

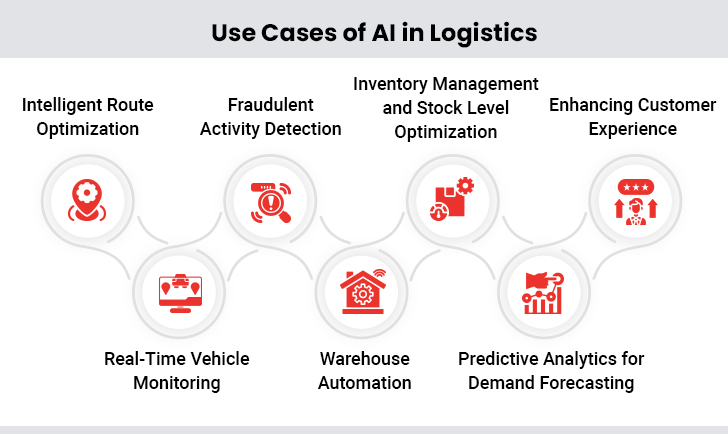

Primary Use Cases of AI in Logistics and Transportation

Logistics companies are putting AI applications to work in their operations to stay ahead of competitors. These specialized tools deliver measurable improvements in efficiency and help cut costs.

1. Intelligent Route Optimization

AI systems improve delivery efficiency through the simultaneous analysis of several factors. These systems are far more advanced than traditional routing tools. They study live traffic data, weather conditions, delivery schedules, and past patterns to find the quickest delivery paths. Routes change automatically if conditions shift, like a sudden traffic jam. This reduces fuel usage and delivery times. Companies that use AI for route optimization reduce their delivery costs significantly. They achieve this by cutting unnecessary driving and using their vehicles more efficiently.

Example: UPS’ ORION system employs artificial intelligence for enhancing route efficiency, which results in the company saving 10 million gallons of fuel each year.

2. Real-Time Vehicle Monitoring

The role of artificial intelligence in logistics goes beyond simple GPS tracking with the advent of new-age vehicle monitoring systems. These systems collect data from sensors placed on thousands of vehicles, so the whole fleet can be tracked live.

They spot unsafe driving patterns right away, like slamming brakes, speeding, or idling too long. This constant watch helps companies coach drivers better. Fuel use also drops significantly, and accidents become far less frequent. These systems also alert mechanics early by analyzing vehicle health data. This prevents costly roadside failures and lowers maintenance bills.

Example: FedEx uses AI-powered dashboards for real-time visibility of packages and fleet vehicles. This real-time monitoring helps anticipate potential delays, ensuring packages reach their destinations on time.

3. Fraudulent Activity Detection

Supply chains are growing more complex, and this has made AI essential for security in logistics. AI-based fraud detection solutions scan millions of shipments to spot suspicious patterns and stop cargo theft. These systems send instant alerts for unauthorized cargo pickups, suspicious double brokering, and other fraudulent activities.

AI connects securely to law enforcement databases. It reveals hidden criminal networks and new fraud patterns, stopping nefarious activities before major losses occur.

Example: UPS’s DeliveryDefense System uses AI to evaluate shipment information and identify irregularities, protecting against package thefts, transit-fraud, and shipment loss.

4. Warehouse Automation

Warehouse automation is growing rapidly. AI-powered machines have now become critical in modern facilities. Drones track stock perfectly in real-time, even in cramped warehouse spaces. They scan barcodes and tags to update inventory records almost flawlessly.

Robots use advanced sensors to handle and move items deftly, adjusting their grip as they learn. AI thus tackles the onerous cost of manual product picking and saves billions by improving efficiency and reducing errors.

Example: Amazon’s AI-driven warehouse robots sort and move items in warehouses, enabling same-day deliveries for millions of customers.

5. Inventory Management

Managing stock manually can be challenging. AI-based inventory systems help solve this issue. These systems track stock levels in real time. They study past sales and live demand to keep inventory balanced. AI systems also adjust reorder points on their own. This prevents stockouts and reduces storage costs.

AI algorithms in warehouses study product sizes, popularity, and how fast items sell. They then suggest smarter storage configurations. Placing items strategically helps in many ways. Workers find items quickly, get orders out faster, and the whole operation runs more smoothly.

Example: AI systems like Codept help businesses manage supply chains by predicting stock requirements based on historical and seasonal data.

6. Demand Forecasting

Predicting what customers will buy is difficult. Old methods rely heavily on past sales alone. AI-based demand forecasting changes this. It examines far more data: real-time store purchases, customer details, the broader economy, and even weather and social sentiment.

This approach lets businesses predict needs for every product with a high degree of precision. As a result, companies can hold the right amount of stock. Their inventory carrying costs come down. Customers find what they want, when they want it. This accuracy can be transformative for any business.

Example:DHL utilizes artificial intelligence for efficient route planning and to predict increasing demands during busy times. This leads to smarter inventory management.

7. Enhancing Customer Service

AI closes the gap between customer service and logistics operations. Chatbots can handle basic questions about tracking shipments or getting quotes. This frees human staff to work on problems that require empathy, creativity, or adaptability. Companies that use AI see fewer simple queries reaching their busy staff. This is because customers can figure out most answers with the assistance of chatbots.

AI also studies past interactions to offer personalized suggestions to customers. This tailored assistance improves satisfaction levels significantly. After all, customers value smooth service more than anything.

Example: FedEx uses AI deep learning models to offer more precise estimated delivery times to their customers.

Implementing Responsible AI: What IT Really Means for Software Engineering

How to Overcome AI Adoption Challenges in Logistics

AI offers tremendous benefits for logistics, yet its adoption often stumbles. Companies find it hard to implement this technology effectively. To succeed, they need to fix several challenges.

I. Addressing High Initial Investments

The cost of getting started with AI can be daunting for many logistics companies. They can use many approaches to reduce this burden.

- Roll out changes in phases rather than all at once

- Look for AI services with subscription models that turn large purchases into smaller expenses

- Compare long-term gains against upfront costs

- Partner with vendors who provide payment flexibility

Money becomes less of an issue when companies target areas where AI pays off quickly. To cite an example, starting with warehouse automation may bring swift returns that can be used to fund future AI projects.

II. Improving Data Quality and Availability

AI in logistics and supply chains needs reliable data to work well. To improve data quality, companies should take these steps:

- Run data checks to uncover gaps

- Set up standard ways to collect data

- Use tools to clean up old data

- Set up clear governance rules that maintain accuracy

Many companies create dedicated teams to keep information flowing smoothly into AI systems. This creates a strong foundation for making reliable decisions using AI.

III. Overcoming Workforce Resistance

People often pose bigger challenges than technology when bringing AI into logistics. These approaches work well:

- Showing how AI improves jobs rather than replacing them

- Creating learning programs that fit different jobs and skill levels

- Identifying AI champions in teams to show its benefits

- Talking about clear career paths that include AI skills

Companies should involve employees in helping choose and set up the systems. This gives the staff a stake in making things work.

IV. Managing System Integration

AI systems may fall short if they cannot work with existing systems. Teams should follow these steps to connect everything smoothly:

- Map all current systems and connection points before starting

- Choose AI tools that easily connect to older systems

- Set clear rules for how different systems share data

- Run proper tests to make sure everything works well

Steps to Implement AI in Logistics Operations

For businesses ready to embrace AI, here’s a practical roadmap to ensure success:

1. Evaluate Current Operations

A complete examination of existing processes creates the foundation for successful AI implementation. Companies should map their workflows, spot bottlenecks, and set up baseline performance metrics. They must check if their infrastructure can support AI applications. Teams should also evaluate their readiness by checking how well their current systems work with AI solutions. This initial review helps spot areas where AI can add value.

2. Identify AI Use Cases

After the review, companies should rank potential use cases based on their business effect and how complex they are to implement. Projects with high impact and low complexity make great starting points for AI in transportation and logistics. Teams from operations, IT, and finance should work together to pick use cases that match their strategic goals. They should also run feasibility studies to see which AI tools can solve their operational challenges and deliver real gains.

3. Choose the Right Vendor

The right vendor should have deep expertise in logistics and a solid track record. Companies should check if their potential partners have worked on similar projects and if their systems will work with existing ones. Selection criteria must include options to scale up, support services, and transparent costs. The vendor should offer contracts that clearly mention timelines, performance guarantees, and knowledge sharing. This will build partnerships that benefit both sides.

4. Develop a Proof of Concept

Companies should run controlled trials to check the real-world performance of AI applications before full rollout. These proofs of concept need clear goals, timelines, and success metrics. They help find hidden issues before bigger commitments are made.

5. Scale Gradually

After validating the concept, companies should scale the application step by step and add features as they expand. They should also step up strong measurement systems to track its technical metrics (e.g., algorithm accuracy) and business performance (e.g., cost savings). Such a phased approach lets teams learn and adjust as AI’s role across the organization grows.

Future Trends on AI in Logistics Operations

The future of logistics will see deeper integration of AI with other advanced technologies, and create new possibilities:

I. AI and IoT Integration

The combination of AI and the Internet of Things creates powerful synergies throughout the supply chain. Containers with sensors transmit location, temperature, and handling data to AI systems that study their conditions in real time. This integration does much more than simple tracking. It helps predict maintenance needs, since equipment problems can be spotted much before failures happen. It also adjusts routes and schedules automatically when conditions change. This creates truly adaptive logistics networks.

II. Blockchain Integration

AI and Blockchain create unmatched transparency and security in logistics. Their combination helps track products reliably from manufacturing to delivery. It solves the problem of counterfeit products in pharmaceuticals, electronics, and luxury goods effectively.

AI and Blockchain systems do more than just track items. They process payments automatically through smart contracts when certain conditions have been met. They also help create verifiable documentation that regulatory systems can process easily. This makes international shipments smoother.

III. Hyper-Personalized Deliveries

AI’s next frontier focuses on highly personalized delivery experiences. Advanced algorithms study past orders, preferences, and habits to customize delivery options. This customization also covers delivery times and packaging choices. Soon, AI may even sense customer needs before an order is placed. This anticipatory service will result in improved customer loyalty. It will strengthen the relationship between logistics providers and end consumers.

Summing Up

The emergence of artificial intelligence in logistics signals a major shift for the sector. It creates exceptional possibilities for increased efficiency, innovation, and accuracy. Today, AI is changing all parts of logistics operations, from improving route planning to detecting fraud and managing inventory.

Successfully tackling the obstacles in AI implementation within logistics is essential, with the benefits vastly exceeding the drawbacks. By integrating AI with assistance from a reliable AI development partner, companies can secure a competitive advantage, ensuring they surpass customer expectations.